Does your CFR or BASF test engine not deliver stable measurement results and the engine defects are accumulating? Just right for MIBO.tech!

We disassemble your test engine down to the last screw! We clean, assess and restore every component and ultimately restore it to a condition that far exceeds the original state of the art. Components that are not within specification are expertly adjusted and replaced!

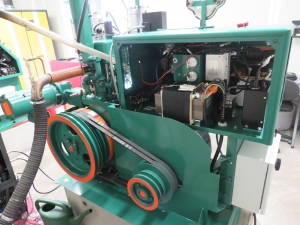

stageone

Overview control panel

Refurbishment control panel

- Metalworking

- Primer / Rust protection

- Painting in desired color

Refurbishment components

- Cleaning

- Repair

- Paintwork

- Function test

- Calibration

New junction box

- Compleately new power contactors

- 110V & 230V socket with earth leakage circuit breaker

- Main switch for safe disconnection

- Emergency stop switch for emergencies

- Fault-free actuator switch (Compression Ratio)

- Touch-proof wiring according to VDE specifications

- New toroidal transformer

- New ignition system if required

- Single-phase control transformer is newly integrated in the control console.

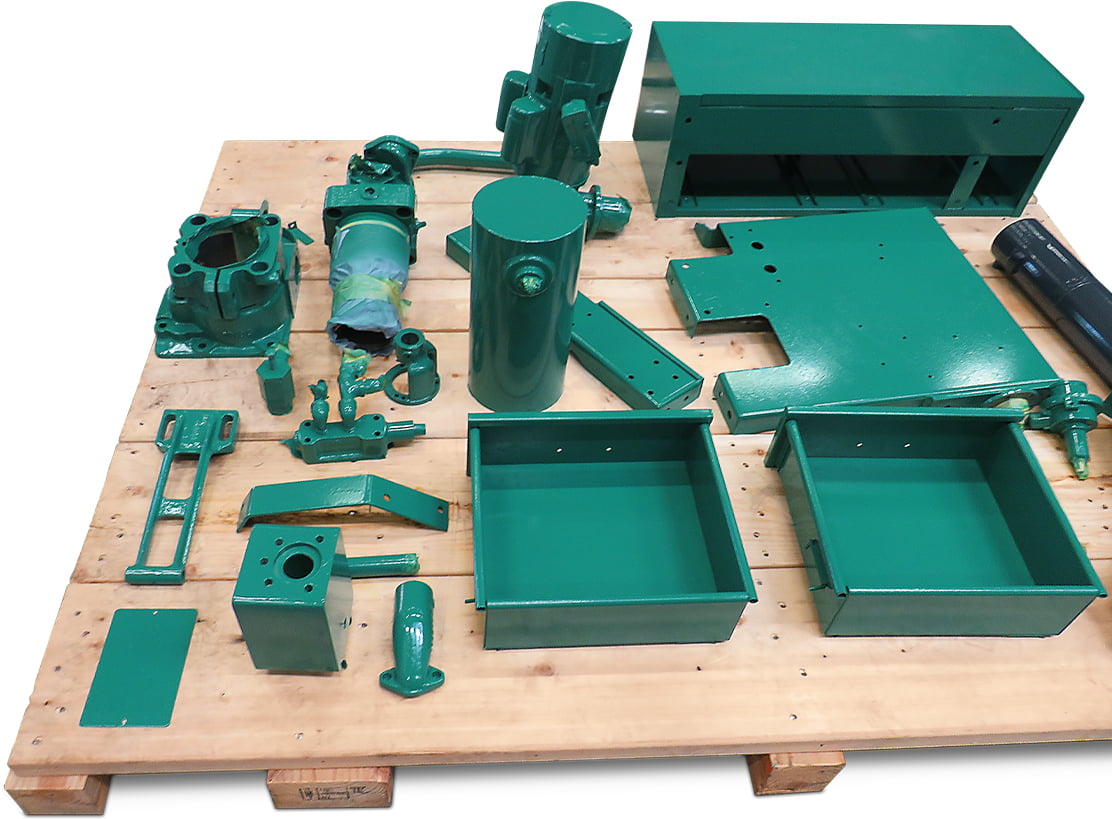

Housing preparation

Our claim - quite simple!

Whether it's the metalworking, the rust protection primer for increased impact resistance or the final 2-K paint job in the colour of your choice, you will be completely thrilled with the new housing of your test engine!

Each component is carefully and industrially cleaned in a slightly alkaline solution that has been specially added for MIBO.tech. We have developed a precise schedule for the case preparation and the craftsmanship of our employees ensure that each case is restored to perfection with skilful handcrafting. That is our claim - quite simple!

At a glance

- Metalwork

- Cleaning of components

- Priming

- Rust protection

- Painting in the colour of your choice

- and much more...

Component refurbishment

You can be sure of that!

Every test engine is a little different! Whether through internal conversions, individualisations or new models or expansion stages from CFR or BASF. We are prepared for everything and know all specifications, designs and modules. Therefore, the preparation of electrical, analogue and technical components is no problem at all for us.

We take your test engine apart piece by piece down to the last screw, clean, repair or replace each component as necessary and in consultation with the customer! After extensive function tests and tolerance measurements of the individual components, we create test protocols and adjust everything to each other. We then test again and ensure that your test engine subsequently delivers good test results again. You can be sure of that!

At a glance

- Cleaning & visual inspection

- Repair & refurbishment

- Function tests

- Tolerance measurement

- Priming & Painting

- Test engine assembly

- Test bench/test run/TSF test

- Test protocols

Junction box

Safe & sustainable

Because of our extensive practical experience in operating test engines, we know that highest quality is the highest priority, especially in the area of switch cabinet construction.

The design of your new junction box includes a compact and contact-safe solution that ensures safe operation through sustainable planning.

Initial start-up is no problem at all either thanks to our first-class support! We can work with you to determine which electrical connections you need and help you design the power supply. Another benefit is the simplified power connection on the connecting cables. You only need one connecting cable since a 110v control transformer is integrated into Steuerpult, which makes planning and commissioning the engine much easier. Even connections to external devices won’t be a problem in future! Regardless of whether you use 110V or 230V sockets, the MIBO.tech junction box has the right sockets with RCD protection for immediately supplying cooling towers or display units with power. Due to the contact-safe terminals in the junction box, you no longer need to worry about electrical work safety, and quick repairs or additional wiring is now even easier to realise.

At a glance

- Completely new contactors

- 110V and 230V sockets with RCD circuit breakers

- Master switch for safe activation

- Terminal strips (touch safe)

- 110V protection “Starting Relay”

- 400V protection “Mag.Switch 3 Phase”

- Single phase control transformer 400V > 110V / 5000VA

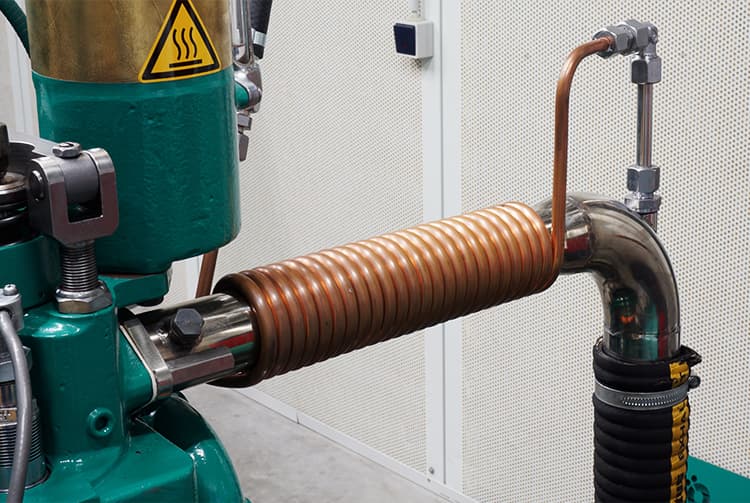

Water Cooled Exhaust Kit

Suitable for all CFR & BASF test engines

Set consisting of:

- Water-cooled stainless steel exhaust with prefabricated exhaust gas temperature measuring point

- Exhaust hose with stainless steel reinforcement

- 110V solenoid valve for automatic cooling water control

- Cooling water connection hoses (1/4" fitting connection)

- Mounting accessories

Part.No. MIM0100-1

Piping kit (PVC)

Realised in no time

The PVC piping kit from MIBO.tech is light, flexible and easily replaces the solid steel/stainless steel counterpart from CFR. By simply gluing and screwing the components together, a pipe path of 5 metres can be realised in a very short time and can be easily extended if required.

The entire system also comes with a vacuum system + water trap that can be drained through a ball valve on the CFR motor. The pipes and fittings have a pressure resistance of PN16 and are extremely stable.

The PVC piping kit is reliable and maintenance-free from many years of experience, many MIBO.tech customers have relied on this system for years!

Part.No. MIM0100-1

Of course, we go one step further and transport your test engine into the 21st century.

In addition to the stageone control panel refurbishment, we offer options for digital control and monitoring devices on request. In this way, you can digitally control and monitor all important processes in the future.

we call it adddigital

service

Our service technicians are always ready to help you!

shipping

Perfect shipping, sustainable and on time, as agreed.

interested?

We would also be happy to convince you of our products in a personal meeting and explain exactly what we can do for you.

Michael Böhnke

Business Leader

Phone: +49 (0) 22 46 . 94 86 850

Mibö Prüfmotoren Technik Teile GmbH

Walterscheid-Müller-Str. 5

53797 Lohmar

Germany

Contact:

Tel.: +49 (0) 2246 9486850

Fax: +49 (0) 2246 9486852

Email: office@miboegmbh.de

Does your CFR or BASF test engine not deliver stable measurement results and the engine defects are accumulating? Just right for MIBO.tech!

We disassemble your test engine down to the last screw! We clean, assess and restore every component and finally produce a condition that far exceeds the original technical state. Components that are not within specification are expertly adjusted and replaced!

Preparation control panel

Part.No. MIE0100-0

Preparation of existing control panel

- Metalworking

- Primer / Rust protection

- Paint in color of your choice

Preparation of all components

- Cleaning, repair, painting

- Function test, calibration

New connection box

- completely new power contactors

- 110V & 230V socket with RCD protection switch

- Main switch for safe release

- Emergency stop switch

- Faultless actuator switch (Compression Ratio)

- Touch-proof wiring according to VDE specifications

- New toroidal transformer

- New ignition system if required

- Single-phase control transformer integrated

(Intrinsically safe due to power contactors and thermal switches)

Housing preparation

Our claim - very simple!

Whether the metalworking, the rust protection primer for increased impact resistance or the final 2-K paint in the color of your choice, the new housing of your test engine will inspire you completely!

Each component is carefully and industrially cleaned in a slightly alkaline solution specially additivated for MIBO.tech.

We have developed a precise schedule for the case restoration and the craftsmanship of our employees ensure in skillful manual work to restore each case perfectly. That is our claim - quite simple!

At a glance

- Metalworking

- Cleaning the components

- Primer

- Rust protection

- Paint in color of your choice

- And much more...

Component repair

You can be sure of that!

Every test engine is a little different!

Whether by internal conversions, individualizations or new models or expansion stages of the company CFR or BASF. We are prepared for everything and know all specifications, construction methods and modules. Therefore, the preparation of electrical, analog and technical components is no problem at all for us.

We disassemble your test engine piece by piece down to the last screw, clean, repair or replace each component according to (on website the "N" is small) necessity and agreement with the customer! After extensive function tests and tolerance measurements of the individual components, we create test protocols and adjust everything to each other. After that we test again and make sure that your test engine delivers good test results again. You can be sure of that!

Process at a glance

- Cleaning

- Visual inspection

- Repair/Refurbishment

- Function tests

- Tolerance measurement

- Primer/paint

- Test engine assembly

- Test bench/test run/TSF test

- Test protocols

- Quality control

- Shipping Management

Connection box

Safe & sustainable

Due to our many years of practical experience in the operation of test motors, we know that the highest quality has the highest priority, especially in the area of control cabinet construction. The design of your new terminal box includes a precise energy process, sustainable planning and ensures safe operation.

With our first-class support, there are also no problems during commissioning! Together with you, we determine the requirements and manufacture your terminal box exactly according to your needs. Thus, suitable wiring ducts as well as cable protection conduits, cable tie holders, separators and touch-proof terminal strips find their place in your new control cabinet.

Process at a glance

- completely new power contactors

- 110V & 230V socket with RCD protection switch

- Main switch for safe release

- Clamping strips (touch-proof)

- 110V contactor "Starting Relay" - Part.No. MIE0101-1

- 400V Contactor "Mag.Switch 3 Phase" - Part.No. MIE0101-2

- Setting control transformer 400V > 110V / 5000VA - Part.No. MIE0101-3

Water Cooled Exhaust Kit

Suitable for all CFR & BASF test engines

Set consisting of:

- Water cooled stainless steel exhaust with prefabricated exhaust gas temperature measuring point

- Exhaust hose with stainless steel reinforcement

- 110V solenoid valve for automatic cooling water control

- Cooling water connection hoses (1/4“ Fitting connection)

- Mounting equipment

Piping Kit (PVC)

Realized in the shortest time

The PVC piping kit from MIBO.tech is lightweight, flexible and easily replaces the solid steel/stainless steel counterpart from CFR. By simply gluing and screwing the components, a pipe path of 5 meters can be realized in a very short time and is easily expandable if needed. The entire system (no comma) also comes with a vacuum system + water trap that can be drained through a ball valve on the CFR motor (no comma). The pipes and fittings have a pressure resistance of PN16 and are extremely stable.

The PVC piping kit is reliable and maintenance-free from many years of experience, many MiBoe.tech customers trust in this system for years!

service

Our service technicians are always ready to help you!

shipping

Perfect shipping, sustainable and on time, as agreed.

interested?

We would also be happy to convince you of our products in a personal meeting and explain exactly what we can do for you.

Michael Böhnke

Business Leader

Phone: +49 (0) 22 46 . 94 86 850

Mibö Prüfmotoren Technik Teile GmbH

Walterscheid-Müller-Str. 5

53797 Lohmar

Germany

Contact:

Tel.: +49 (0) 2246 9486850

Fax: +49 (0) 2246 9486852

Email: office@miboegmbh.de