In addition to the stageone control panel overhaul (legacy panel), we are also offering you the option for digital control units upon request. Which means that in future, you’ll be able digitally control and monitor all important processes - we call it adddigital.

we call it adddigital

Electric

Junction box

Safe & sustainable

Because of our extensive practical experience in operating test engines, we know that highest quality is the highest priority, especially in the area of switch cabinet construction.

The design of your new junction box includes a compact and contact-safe solution that ensures safe operation through sustainable planning.

Initial start-up is no problem at all either thanks to our first-class support! We can work with you to determine which electrical connections you need and help you design the power supply. Another benefit is the simplified power connection on the connecting cables. You only need one connecting cable since a 110v control transformer is integrated into the control panel, which makes planning and commissioning the engine much easier. Even connections to external devices won’t be a problem in future! Regardless of whether you use 110V or 230V sockets, the MIBO.tech junction box has the right sockets with RCD protection for immediately supplying cooling towers or display units with power. Due to the contact-safe terminals in the junction box, you no longer need to worry about electrical work safety, and quick repairs or additional wiring is now even easier to realise.

At a glance

- Completely new contactors

- 110V and 230V sockets with RCD circuit breakers

- Master switch for safe activation

- Terminal strips (touch safe)

- 110V protection “Starting Relay” - Part.No. MIE0101-1

- 400V protection “Mag.Switch 3 Phase” - Part.No. MIE0101-2

- Single phase control transformer 400V > 110V / 5000VA - Part.No. MIE0101-3

Oil & cooling water

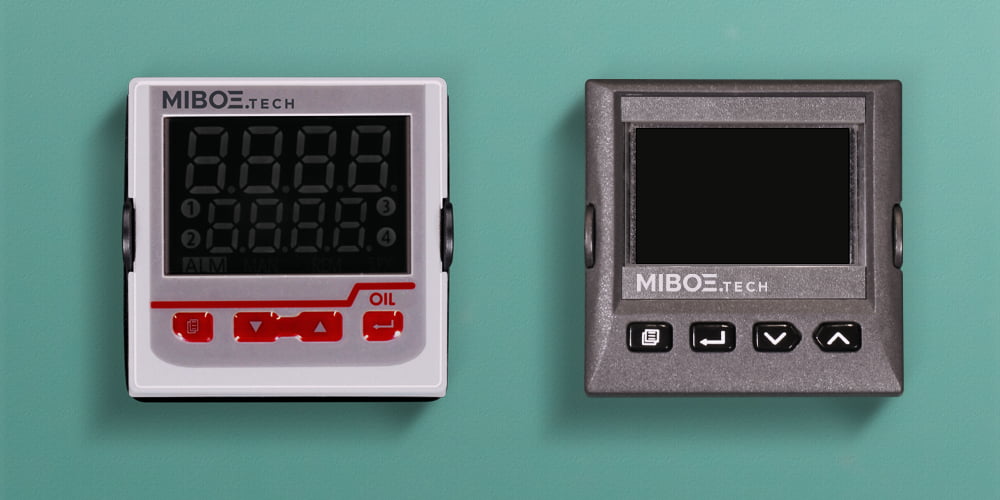

Digital oil pressure monitoring & display

- Part-No.

- MIE0120-5

- Spec.

- ROZ / MOZ /F5

- Price:

- on request

Hot pressure

Increased demands are placed on the test engine’s greasing system due to the high speeds and heavy mechanical burdens. The digital oil display with automatic shut-off in case of incorrect oil pressure constantly checks and shows the current system pressure in PSI or bar (depending on desired unit) on the three-colour display. The pressure sensor is located in the heart of the display, making previous oil pressure hoses in the console housing superfluous - less is more!

Combination makes the difference

Combined with our digital water temp. control & display (part no.: MIE0120-7), in future you won’t need to think about oil pressure or water temperature. Because we’ve already done it for you. The system switches off the test engine as soon as tolerance values are undershot and then displays the relevant error message.

Digital water temp. monitoring & display

- Part-No.

- MIE0120-7

- Spec.

- ROZ / MOZ /F5

- Price:

- on request

Cool water

High temperatures can cause various types of damage to your test engine. You always have control over cooling your test engine with our digital water temperature control. Two high-precision industrial sensors constantly monitor the cooling water temperature and the temperature in the condenser, so that the engine can be immediately shut off in case of even the smallest temperature increase and to prevent further damage.

Combination makes the difference

Combined with our digital oil pressure control & display (part no.: MIE0120-5), in future you won’t need to think about oil pressure or water temperature. Because we’ve already done it for you. The system switches off the test engine as soon as tolerance values are undershot and then displays the relevant error message.

Digital Safety Box

Oil pressure and cooling water control unit

- Part-No.

- MIE0120-2A

- Spec.

- ROZ / MOZ / F5

- Price:

- on request

Little superheros

You can’t see them, you can’t hear them, but when you need them, they’re immediately there protecting your test engine from failure or damage! The Digital Safety Box uses sensors to monitor oil pressure and water temperature. So you can be sure that your test engine is always well lubricated and well cooled when doing its job.

Into the 21st century

Together with our digital oil pressure display (part no. MIE0120-5) and digital water temp display (part no. MIE0120-7), we’re catapulting your test engine directly into the digital world of technology. Combined, you get a discounted system that allows you to constantly keep an eye on the oil pressure and cooling water temperature, giving you a complete overview of the most important parameters.

Temperature control

Digital oil temperature control

- Part-No.

- MIE0110-0

- Spec.

- ROZ / MOZ /F5

- Price:

- on request

Perfect results through perfect heat management

Forget everything you know about oil temperature controls! The new and completely digital control unit has a simple menu structure and heats oil precisely and easily to the set target value so that your CFR engine is ready for operation as quickly as possible. Super simple - perfectly adapted to your test engine!

Impressive functionality within the ASTM standard framework

The HMI control interface makes it possible! The new temperature control unit has extensive options for setting up all functions so that it can meet your individual requirements. From commissioning via a password-protected area to a completely customisable user menu, you’re always able to adjust parameters to fit your needs.

Overshooting is a thing of the past!

Adjusted to your requirements, the Cutback System ensures precise regulation and prevents temperature overshooting. Which means you can concentrate on the important things - results!

Control panel in accordance with protection type IP65

With its high-quality, three-colour LED display, the control panel meets all industry requirements and can be used in dusty or damp areas without issue.

Digital intake air & mixer temperature control

Intake-Air Temp

- Part-No.

- MIE0110-1

- Spec.

- ROZ / MOZ

- Price:

- on request

Mixer Temp

- Part-No.

- MIE0110-2

- Spec.

- ROZ / MOZ

- Price:

- on request

Adjusted to your requirements

Probably one of the most important innovations in digitising your test engine is the digital intake air & mixer temperature control. Specially adjusted to CFR test engines, it conditions suction air and air-fuel-mixture to the set target value. Our goal was to develop a module that could be individually adjusted to your requirements within the framework of the ASTM standard.

Simple - logical - controllable

A clear, and above all logical, menu structure ensures that commissioning and operation is as simple as possible. The customisable system also offers the option of avoiding unauthorised access using password protection and assigning rights, preventing incorrect operation.

No overshooting - no stress

The single Cutback System ensures that the target value is precisely regulated, preventing temperature overshooting. Thanks to built-in self-optimisation, you can be sure that you’ll always get perfect measured values - day after day - again and again!

Control panel in accordance with protection type IP65

With its high-quality, three-colour LED display, the control panel meets all industry requirements and can be used in dusty or damp areas without issue.

More features

digital counter

- Part-No.

- MIE0130-1

- Spec.

- ROZ / MOZ

- Price:

- on request

Perfectly replaced - optically and technically

The new MIBO.tech digital counter offers huge advantages compared to the old mechanical CFR counters. Not only are they not on the market anymore, if they are not properly maintained, they are prone to blockages and even complete failure! The old counter can easily be replaced with the new MIBO.tech digital counter. Mounting holes are identical and the extended shaft fits the digital counter’s rotary transducer effortlessly.

“must have” not “nice to have”

The integrated BOSCH air pressure sensor constantly measures air pressure in the laboratory, which means there is no need for daily, manual correction using a table in accordance with ASTM D2699 / D2700! If you want to use your own air pressure sensor, that's not a problem. The BOSCH sensor air pressure can be set automatically in the program using a barometer you have calibrated. The required octane number is then displayed in the main display in either MON or RON according to the standard table, making it easier to select input fuels. Likewise, all three Venturi nozzle settings can be preset in the settings depending on altitude, so you always have everything under control.

The MIBO.tech digital counter isn’t a “nice to have”, it’s an absolute “must have” for your test engine!

Digital operating hours counter

- Part-No.

- MIE0120-4

- Spec.

- ROZ / MOZ

- Price:

- on request

Perfect for every test environment

The MIBO.tech backlit digital hour counter is ideal for use in CFR and BASF test engines. The internal battery promises a lifespan of 10 years and cannot be reset! The counter underneath is used as a maintenance interval display. It is used for optimally monitoring maintenance intervals and can be reset to "0" at any time after maintenance using the reset button. The operating hours counter can be used at 50Hz or 60Hz - perfect for every testing environment.

digital temperature process display

Mounting variant

- Part-No.

- MIE0120-0

- Spec.

- ROZ / MOZ

- Price:

- on request

Installation variant

- Part-No.

- MIE0120-1

- Spec.

- ROZ / MOZ

- Price:

- on request

Trust is good - control is better

The cooling water temperature plays a crucial role when it comes to flawless test results! To ensure that you always have full control over all parameters, we offer you a simple but effective solution with our digital cooling water temperature display.

Feels uncompromising

The installed cable temperature sensor is uncompromisingly shielded from all mechanical stresses and environmental influences by a protective sleeve made of stainless steel, and the silicone cable used enables operating ranges from -50°C to +180°C.

For us a matter of course

By using a high-quality compression fitting at the measuring point, you can safely and easily dismantle the cable temperature sensor in case of maintenance or repair - of course.

Not unnecessary - precisely thought out

Whether as a retrofit kit in a perfect stainless steel housing or directly integrated in the control panel - the digital cooling water temperature display is definitely not a "nice to have"! The system saves you and your test engine from unpleasant surprises, damage or even incorrect test results - and all with just one display.

Flow control

- Part-No.

- MIE0120-3

- Spec.

- ROZ / MOZ

- Price:

- on request

Small component - big effect

Failure of the incoming cooling water to the condenser can cause severe damage to the entire cylinder, up to total failure of your test engine. With this small component, you not only protect your test environment, but your employees will also enjoy a safe application!

Safety in the best case

The flow monitor is integrated into the safety network of the control system and functions purely mechanically. It permanently controls the cooling water inflow, so the test engine can only start when the cooling water is running.

service

Our service technicians are always ready to help you!

shipping

Perfect shipping, sustainable and on time, as agreed.

interested?

We would also be happy to convince you of our products in a personal meeting and explain exactly what we can do for you.

Michael Böhnke

Business Leader

Phone: +49 (0) 22 46 . 94 86 850

Mibö Prüfmotoren Technik Teile GmbH

Walterscheid-Müller-Str. 5

53797 Lohmar

Germany

Contact:

Tel.: +49 (0) 2246 9486850

Fax: +49 (0) 2246 9486852

Email: office@miboegmbh.de